Intelligent Pig Inspection System (UT)

We conduct reliable detection of defects on the inside and outside of pipelines economically and in a short period of time.

This system offers reliable detection of defects on the inside and outside of pipelines economically and in a short period of time.

Using the magnetic flux leakage method (MFL), it is possible to detect defects on the inside and outside surfaces of pipelines from the inside.

| Features |

|

|---|---|

| Benefits |

|

| Major Application |

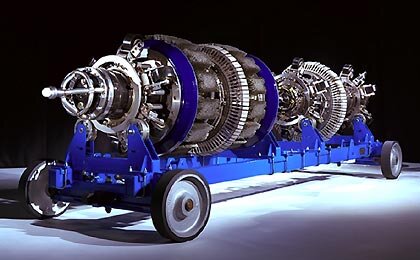

This method is applicable for inside and outside inspection of 6-to-56-inch pipelines. |

| Specifications |

|

| Processes and Methods |

|

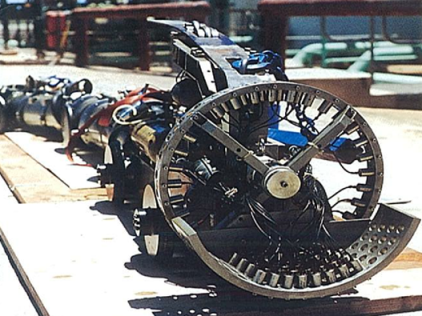

Features of MFL Inspection Machines

Magnetizing device installed on the pig locally magnetize pipelines and generate a magnetic flux in the axial direction, so that leakage flux from corrosion is detected and measured by the sensor for inspection.

By using two magnetizers with different magnetic forces to measure the flux leakage, corrosion on the outer and inner surfaces can be measured separately.

Data is not displayed as absolute values, but as percentages of the original pipe wall thickness.

If there is more than 80% wall thinning, we provide a preliminary report at the time of measurement, conduct data analysis, and after 30 to 40 days submit a final report.

This method allows accurate detection of wall thinning.

We can measure wall thinning in both pipelines of gaseous and liquid fluids.

Ultrasonic method (UT) can be used to detect defects on the inside and outside surfaces of pipelines from its inside.