Safety Initiatives

Commitment to Safety

Cosmo Engineering Co., Ltd. is committed to becoming a leading safety company in the industry by setting company-wide safety goals, establishing a framework for systematic safety activities, breaking down internal and external barriers, and continuously exchanging ideas to foster growth.

We have set the goal of achieving and maintaining zero accidents and disasters, and we are continuously improving and reviewing our safety culture while promoting a change in awareness.

Pillars of Safety

FY2025 Health and Safety Targets

- Comply with laws, regulations, and internal rules to achieve zero major defects.

- Eliminate recurrence of accidents by effectively sharing defect cases, ensuring the implementation of preventive measures, and preventing the fading of memory regarding major accidents.

- We improve the on-site work environment through the use of safety management systems and risk assessment activities throughout the construction cycle.

- Ensure that all personnel involved in construction work maintain a high level of safety awareness and act autonomously.

- Enhance and implement safety and health education to improve employees' knowledge and skills regarding safety and health.

- Promote mental health consultations with occupational physicians and analyze and improve the workplace environment to prevent the occurrence of mental health issues.

Safety Framework

Based on ISO 45001:2018 (JIS Q 45001:2018), the international standard for occupational health and safety management systems, we introduced our own "Safety and Health Management System" (SMS) company-wide in July 2020 as a framework for creating a safe working environment.

The purpose of this system is to prevent workplace injuries and illnesses and to provide a safe and healthy workplace. Specific goals include "compliance with rules," "self-directed actions (thinking and acting independently)," and "self-directed individuals and organizations."

We aim to continuously improve safety levels by annually refining the PDCA (Plan-Do-Check-Act) cycle for safety management initiatives at the workplace.

New Challenges for Safety

Digital Transformation of Safety Management

In response to changes in the social environment surrounding us, we are promoting the efficiency of on-site safety management operations using digital technology under the name of "Safety DX Activities" with the aim of improving productivity and safety levels.

<Utilization of Generative AI>

We are experimenting with the creation of a system that allows for easy retrieval of various information such as internal regulations, relevant laws and regulations, and past incident cases. Currently, we are not only retrieving various information but also developing tools to support the prior consideration of safety measures related to construction work.

<Introduction of an information sharing environment>

We are introducing software that enables the sharing of information such as on-site videos, photos, and management documents both internally and externally via the cloud. We are also working to improve the efficiency of safety management by utilizing remote monitoring devices such as wearable cameras and drones.

<Digitization of safety-related laws and regulations>

We have made it possible to easily check illustrated safety-related laws and regulations on-site using smartphones and tablet devices. (Smartphones are provided to all employees.)This is helping with compliance with safety management regulations.

<Introduction of Digital Signage>

We have created original safety content with the aim of increasing the points of contact between people and digital technology. Displays and monitors have been installed at construction site bulletin boards and worker break areas for viewing. This is helping to improve safety awareness at the site by facilitating closer communication between workers and supervisors.

Utilizing past failure cases

Risk assessment involves identifying the hazards or risks associated with construction work, estimating the magnitude of those risks, clearly identifying the risks that must be addressed prioritarily, and determining measures to avoid or reduce risks, then incorporating these into the construction process to avoid or reduce hazards and risks.

We have created a database that applies this risk assessment to failure cases spanning approximately 20 years. By creating a system that allows us to apply this database, categorized by construction type and work classification, to upcoming projects and prepare countermeasures in advance, we ensure that the same failures are not repeated.

Additionally, we are exploring mechanisms to directly feed back the results to the construction site.

Safety created by everyone

Cooperation with affiliated companies

Through project work, we are deepening mutual understanding and cooperation with partner companies to improve technical capabilities and ensure safety. We have established a cooperative association (Kikuyukai) with 43 member companies, and regularly exchange opinions and conduct activities to raise safety awareness. We also organize events such as safety conferences and training tours to promote technical exchange.

(Simultaneous broadcast via Teams)

Enhancing Safety Knowledge

To ensure that all employees and subcontractors acquire the necessary safety knowledge and skills to confidently provide safety guidance on-site, we conduct an annual "Safety Master Exam" to assess understanding of safety laws and company safety standards. Top performers are designated as "Safety Masters" and take the lead in promoting safety management and activities for one year. (2024 Safety Master Certification: 10 people / 289 examinees, including partner company employees)

Raising Safety Awareness

We solicit submissions from both inside and outside the company, conduct a rigorous review, and select the "Safety Management Slogan" for the following year. For the 2025 Safety Management Slogan selection, the best work was chosen from 1,756 submissions.

【2025 Safety Management Slogan】

"It's dangerous!" The courage to communicate and a heart of gratitude - building a zero-accident workplace together.

Awards for Excellent Safety Management Activities

With the aim of enhancing safety awareness and promoting disaster prevention, we selected and honored partner companies that achieved outstanding results in safety and health management activities with the "Outstanding Safety Award," "Excellent Safety Award," and "Accident-Free Award." The award ceremony for the 2024 fiscal year was held at the Tokyo Prince Hotel.

Safety Dialogue

Safety inspections and site visits

Safety inspections involve company management visiting each site to confirm compliance with legal requirements, internal rules and regulations, and measures to prevent recurrence of accidents. Through interviews, we identify potential weaknesses and unique initiatives, fostering passionate discussions aimed at cultivating a safety culture.Through these efforts, honest opinions from the field are directly conveyed to management, enabling us to identify issues and challenges that were previously unrecognized. As a result, we have begun to work together as an organization to address these issues. Furthermore, by sharing best practices across the company, we have created a positive cycle that further motivates employees on the front lines.

Site inspections are conducted to visually confirm safety activities at each location and construction department by visiting actual construction sites. Safety specialists from headquarters or other locations visit the site to assess the situation from an expert perspective and provide guidance on improvement measures.

Unique method of safety level diagnosis

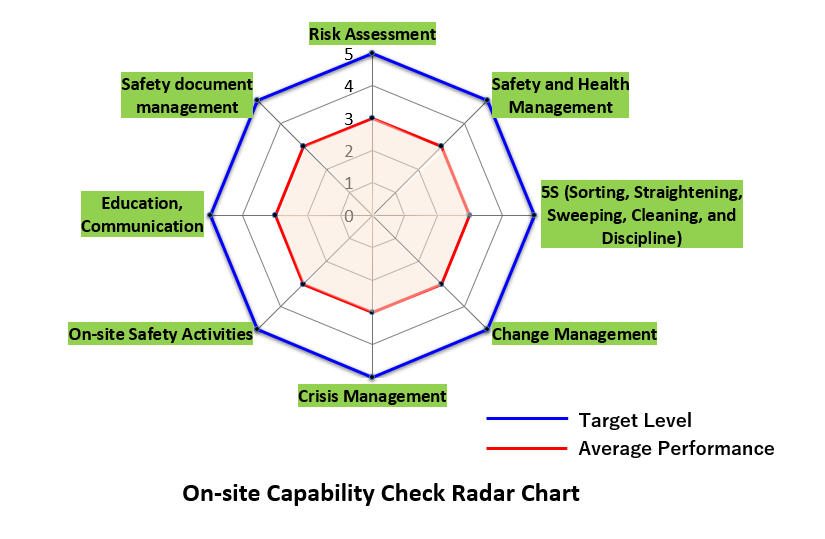

To verify safety activities at each construction site, we have developed and implemented a unique assessment method called the "Site Capability Confirmation Sheet," which evaluates safety management across eight categories.

This assessment method is also utilized in safety inspections and site patrols, with results visualized in a radar chart format, enabling quick and intuitive confirmation. This allows us to immediately identify strengths and areas for improvement in safety management at each site, enabling continuous safety activities.

Furthermore, by sharing diagnostic results internally, best practices are being shared, fostering a culture of mutual improvement and collaboration among construction sites.

Safety record

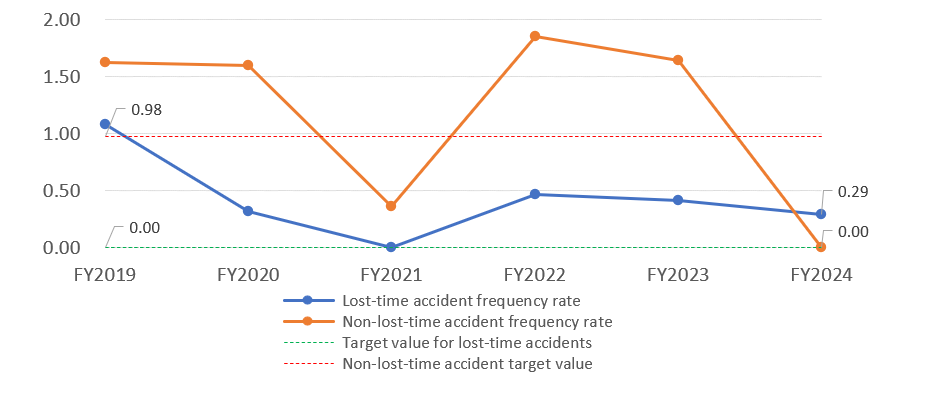

In fiscal year 2024, there was one work-related accident resulting in lost time and one work-related accident without lost time, resulting in an accident frequency rate of 0.29 (the accident frequency rate for the construction industry as a whole in fiscal year 2023 was 1.69, according to the "Labor Accident Trends Survey" results for fiscal year 2023). While this is a better level than the industry average, we will continue to prioritize safety and strive for further improvements in safety standards.

Incidence rate: An indicator used to evaluate the occurrence of occupational accidents, representing the number of fatalities and injuries caused by occupational accidents per 1 million extended actual working hours.