Maintenance Business

We can provide a series of maintenance services from equipment maintenance planning to execution. We support continuous safe and stable operation.

With our extensive maintenance experience, we propose and execute rational maintenance plans from the user's side. In addition, by owning our own engineering department, we can implement equipment and facility modifications in accordance with the timing of maintenance.

Maintenance Plan

- Strategy Development

-

We propose the best maintenance strategy cycle for your facilities based on facility diagnosis, risk assessment, and business planning.

- Maintenance Planning

-

We develop equipment maintenance plans according to the cycles defined in the maintenance strategy. Preventive maintenance reduces unexpected problems and equipment downtime.

Maintenance Construction

- Onstruction Planning

-

We develop budgets for maintenance work and prepare specifications and inspection specifications. We also support for the correspondence with current regulations such as the Fire Service Law, High Pressure Gas Safety Law, and Occupational Safety and Health Law.

- Construction Management

-

We conduct daily inspections and repairs, perform periodic maintenance work, and manage quality, processes, and costs while ensuring "safety" as our first priority.

Records / Evaluation

- Report of Construction Results

-

We prepare reports, organizing the results of conducted facility inspections and construction results.

- Data Analysis and Risk Assessment

-

We propose a maintenance plan for the next and subsequent years based on the inspection and construction results,

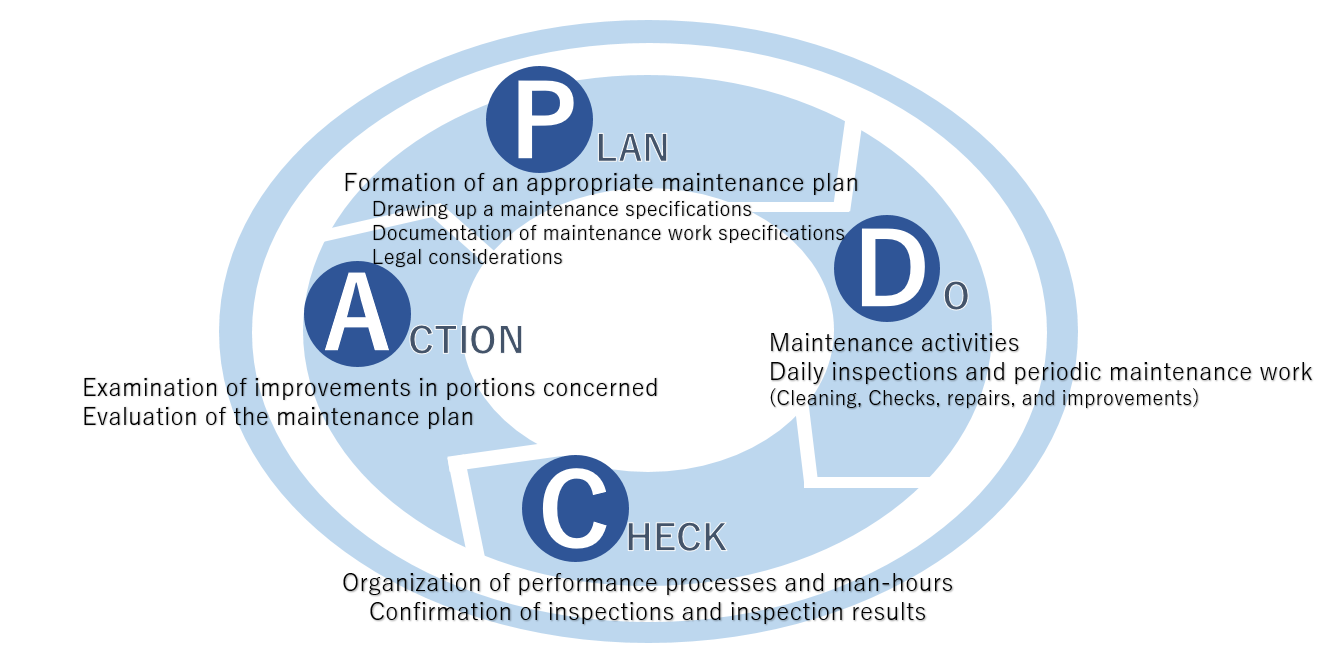

By repeating each PDCA cycle process, we continually provide appropriate maintenance services to our customers.