Keihin Refinery of Toa Oil Co., Ltd.: 24B Pipe Lining Work

Project data

- Customer Name

- Keihin Refinery of Toa Oil Co., Ltd

- Company Address

- Kawasaki City, Kanagawa Pref.

- Construction Name

- Anti-Corrosive Oil Pipe Lining Work

- Date of Completion

- May 1, 2012

- Pipe Quantity

- 24B x 800m (Buried pipe)

What is lining work?

There are many pipes scattered throughout a plant. Some pipes are buried and others are elevated making these pipes difficult to refurbish when found to be corroded. The pig lining method is a specialized process which extends the life span of such pipes. This method coats the pipe lining with a special anti-corrosive coating resin, extending the life span of pipes installed in locations where reinstallation or replacement of pipes would be difficult. This method makes it possible to significantly reduce maintenance costs. We have the flexibility to support a wide range of pipe diameters and fluids by changing the anti-corrosive resin used according to each pipe condition. We have used this method for many pipe lining construction projects on various kinds of pipes.

A pig receiver temporary installed

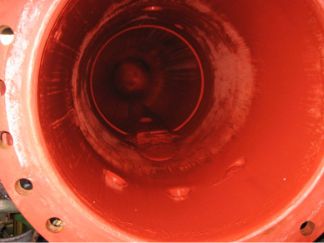

Transfer of the oil in the pipe and cleaning

It is necessary to clean the inside of the pipe prior to implementing the lining work. A pig is driven into the pipe lining in order to remove sludge in the pipe and to conduct degreasing and cleaning with a solvent. This can completely remove oil film on the inside of the pipe. For this project we cleaned pipes that are installed between different plants, so that the operating distance of the pig exceeded 800 meters. We were able to operate the pig without any difficulties and successfully clean the lining of these pipes to the point where the oil film inside the pipes was completely removed.

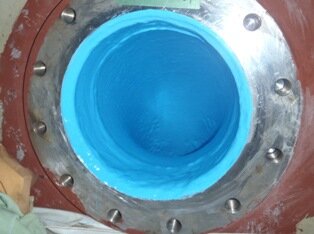

Lining work

We implemented lining work for this project during the period when fire maintenance work was being done at the plant. Since use of flames is prohibited at work sites where resins are used, we conducted all lining work processes during the night and the area was ventilated during the day. Under such circumstances we managed to complete this lining work within the scheduled work period.

The targets for this project were pipes installed in a refinery, and we were only allowed to conduct this project during the period of shutdown maintenance (SDM) where all equipment and facilities of the plant are shut down. In addition, as mentioned before, there were many restrictions regarding fire control and working hours. However, we were able to make the necessary adjustments after having discussions with the related divisions and departments prior to beginning the work. We were able to complete this project thanks to all-round support from the customer and subcontractors.