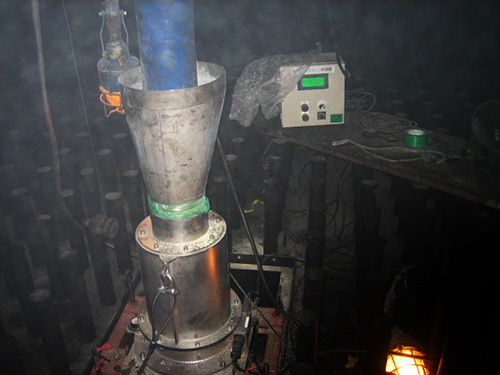

Dense Loading - Catalyst Filling Technology

Technology that fills catalyst densely and uniformly

Maximum difference in height on the surface ±200 mm (Reactor ID is 4 m's case)

Dusting rate of catalyst is comparatively low about 0.2% (This is an experimental value and could vary depending on the strength of catalyst)

Loading velocity: 8-22 m3/hr (reactor radius: 1-4.5 m)

Loading density is increased by 10 - 16% (compared to sock loading) (* Varies depending on the reactor diameter and height, and catalyst type and shape)

| Features |

Clear and low loading cost |

|---|---|

| Benefits |

Dense and uniform catalyst loading |

| Major Application |

Dense catalyst loading |

| Specifications | CEC catalyst loading machine: φ445x960 mm, 70 kg Applicable reactor tower diameter: 1 - 5 m |

Catalyst Change Work in the Nitrogen Atmosphere

Inert entry technology accident-free for more than 35 years

Features: We have extensive know-how implementing this work without accident for over 35 years.

Benefits: Catalyst skimming and extraction under the inert atmosphere in a short period of time

Applications: Work at risk of oxygen deficiency when skimming/extracting catalyst

Specifications: Inert entry technology with our unique development and modification

|