Ohgishima Oil Terminal Co., Ltd.: Cleaning Work for 40B Oil Receiving Pipes

Project data

- Customer Name

- Ohgishima Oil Terminal Co., Ltd.

- Company Address

- Yokohama City, Kanagawa Pref.

- Construction Name

- Cleaning Work for 40B Oil Receiving Pipes

- Date of Completion

- December, 2012

- Pipe Quantity

- 40B×4,600m

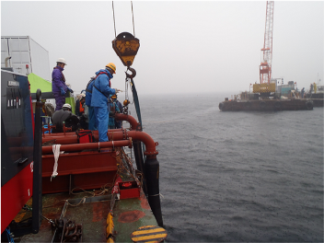

Work in a rough sea

In this project, we conducted cleaning work for 40B underwater oil pipes at a location that had been idle for quite some time. In the past we have been successful in conducting the cleaning of a wide variety of pipe types in various locations. However, because this project would be an offshore operation in the winter season, consideration had to be given to the weather conditions that could have a significant impact on the success of this project.

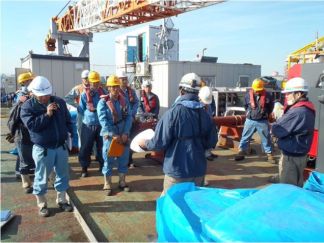

Installation of temporary equipment for cleaning

The target pipe of this project was large, 40B, and long, 4600m, so that we needed to install significantly large-scale temporary equipment for cleaning.

We had to form a convoy composed of a total of five ships: two 2000-kl water-recovery ships for recovering water from the pipe, one 300-kl water-recovery ship, one crane barge, and one monitoring ship, on the ocean side. On the land side, 12 square tanks for recovering cleaning effluent (solvents, degreasing agents, and cleaning water) were installed. Each pig that was used in this project for cleaning was taller than a person and quite heavy, requiring heavy equipment to insert and retrieve them.

Pipe cleaning night and day

More than a decade had passed since the target pipes were last used, resulting in the remaining oil in the pipes becoming firmly affixed to the pipe lining. Taking advantage of our past experience, we decided that when operating the pig we would move it back and forth more frequently than normal in order to remove the oil content firmly affixed to the inside of the pipes. The cleaning effect of the pig can become less effective depending on the speed at which the pig moves through the pipe. For this reason, we continued this cleaning work by operating pigs night and day and as the operators changed shifts any necessary information required for continuing the work was passed on. Through these efforts, we were able to attain the desired cleaning results as planned and complete this project successfully.